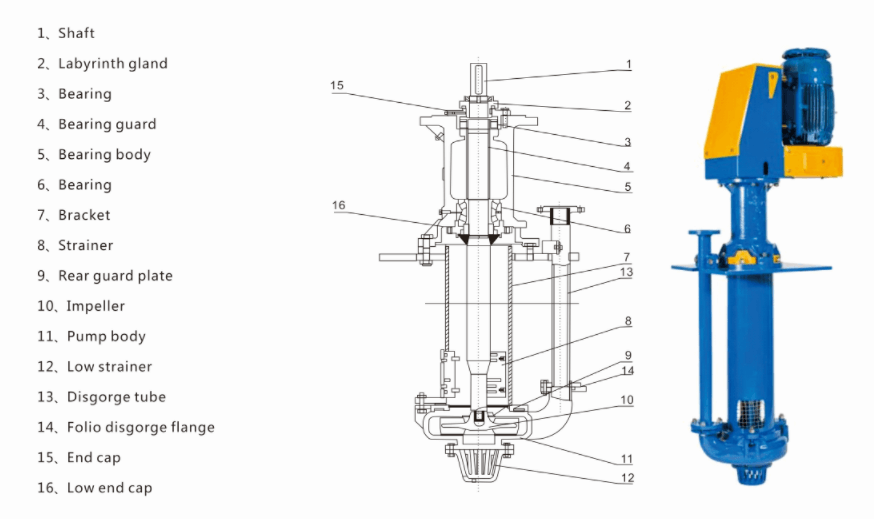

Introduction of SP(R) vertical centrifugal slurry pump

SP (R) type sump vertical pumps are vertical centrifugal slurry pump, which equivalent with Warman SP(R). And they are designed for delivering abrasive, large particle and high density slurries . Wet parts of type SP pump are made of abrasion-resistant hard alloy. All parts of type SPR pump immersed in liquid are lined with special rubber material, which is suitable for non-edge angle abrasive slurries. The depth below the liquid surface of the pumps can be customized.

The SP slurry pump is widely used in mining, power, metallurgy, coal, dredging, building materials, and other industrial lines to pump concentrate, tailings, sludge, and other abrasive and high-density slurries.

Features:

1.Use a double-suction, semi-open impeller design, using hard alloy or rubber impeller.

2.No shaft seal requirement.

3. The gap between the impeller and the guard can be adjusted to ensure the efficient operation of the pump.

4.SP series pump body if made of antifriction metal, and the impeller is made of antifriction metal, rubber or polyurethane.

The submerge part of the SPR pump is coated with rubber, to transmit the corrosive slurry.

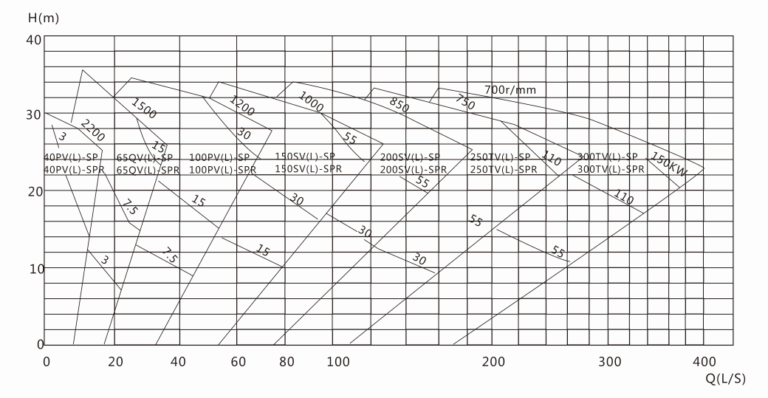

SP/SPR Slurry Pump Selection Chart

SP Sump Pump Performance Chart

| Pump Model | Allowable Max.Power(kw) | Capacity m³/h | Capacity L/S | Head H(m) | Speed n(r/min) | Max.EFF.(%) | Impeller.Dia(mm) |

| 40PV-SP | 15 | 19.44-43.2 | 5.4-1.2 | 4.5-28.5 | 1000-2200 | 40 | 188 |

| 40PV-SPR | 15 | 17.28-39.6 | 4.8-11 | 4-26 | 1000-2200 | 40 | 188 |

| 60QV-SP | 30 | 23.4-111 | 6.5-30.8 | 5-29.5 | 700-1500 | 50 | 280 |

| 60QV-SPR | 30 | 22.5-105 | 6.25-29.15 | 5.5-30.5 | 700-1500 | 51 | 280 |

| 100RV-SP | 75 | 54-289 | 15-80.3 | 5-35 | 500-1200 | 56 | 370 |

| 100RV-SPR | 75 | 64.8-285 | 18-79.2 | 7.5-36 | 600-1200 | 62 | 370 |

| 150SV-SP | 110 | 108-479.6 | 30-133.1 | 8.5-40 | 500-1000 | 52 | 450 |

| 200SV-SP | 110 | 189-891 | 152.5-247.5 | 6.5-37 | 400-850 | 64 | 520 |

| 250TV-SP | 200 | 261-1089 | 72.5-302.5 | 7.5-33.5 | 400-750 | 60 | 575 |

| 300TV-SP | 200 | 288-1267 | 80-352 | 6.5-33 | 350-700 | 50 | 610 |