Product Description

G/GH gravel pumps are type Warman gravel pump which are designed to accommodate the most difficult, most highly abrasive slurries containing solids too large to be conveyed by a regular pump. They are suitable for delivering slurries in mining, explosive sludge in metal melting, dredging in dredger and river courses, and other fields. This model is a high head pump. To increase efficiency, this pump offers a variable frequency drive, silicon-controlled speed control, and multiple speeds and variants.

The gravel pump flow channel is wide, good cavitation performance, high efficiency, wear resistance. It is mainly used for continuous conveying of abrasive materials that are too large for general slurry pumps to convey. It is suitable for dredging, sand suction gravel, dredging rivers, river sand mining, and metal smelting slag transportation.

Shaft seal form: packing seal, impeller seal, mechanical seal.

Transmission mode: V-belt transmission, elastic coupling transmission, gear reducer transmission, hydraulic coupling transmission, variable frequency drive, silicon controlled speed control With multiple speeds and multiple variants, the pump runs under optimal conditions. Long service life, high operating efficiency, can meet a variety of harsh transportation conditions.

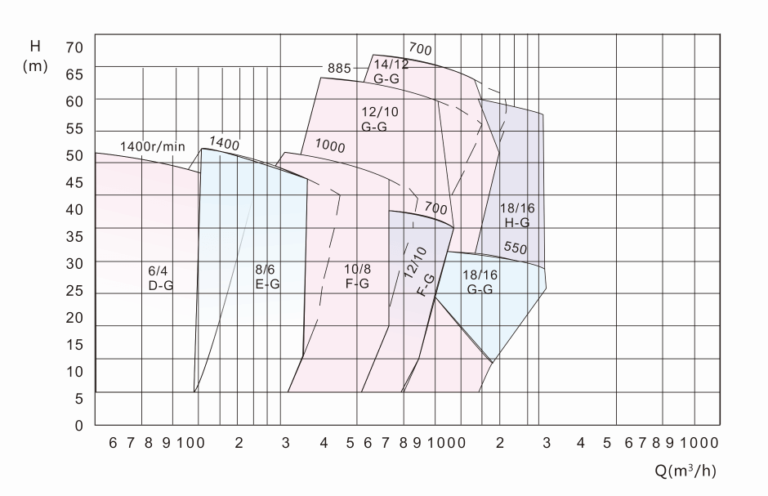

Gravel Pump Performance Chart

Warman Gravel Pump Performance Chart

| Pump Model | Allowable Max.Power(kw) | Capacity m³/h | Capacity L/S | Head H(m) | Speed n(r/min) | Max.EFF.(%) | NPSH(m) | Impeller.Dia(mm) |

| 6/4D-G | 60 | 36-250 | 10-70 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 378 |

| 8/6E/G | 120 | 126-576 | 35-160 | 6-45 | 800-1400 | 60 | 3-4.5 | 378 |

| 10/8S-G | 560 | 216-936 | 60-260 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

| 10/8F-G | 260 | 216-936 | 60-260 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

| 10/8S-GH | 560 | 180-1440 | 50-400 | 24-80 | 500-950 | 77 | 2.5-5 | 711 |

| 12/10F-G | 260 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

| 12/10G-G | 600 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

| 12/10G-GH | 600 | 288-2808 | 80-780 | 16-80 | 350-700 | 73 | 2.0-10.0 | 950 |

| 14/12G-G | 600 | 576-3024 | 160-840 | 8-70 | 300-700 | 68 | 2.0-8.0 | 864 |

| 16/14G-G | 600 | 720-3600 | 200-1000 | 18-44 | 300-500 | 70 | 3.0-9.0 | 1016 |

| 16/14TU-G | 1200 | 324-3600 | 90-1000 | 26-40 | 300-500 | 72 | 3.0-6.0 | 1270 |

| 18/16G-G | 600 | 420-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 |

| 18/16TU-G | 1200 | 720-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 |